In the past decade, the rising consumer preference towards the direct-to-consumer (D2C) ecosystem has seen little-known Indian brands emerge from obscurity and cater to mainstream demand. The growth that followed and the customer trust gained through enhanced engagement and quality commitment worked wonders for many as these D2C companies managed to reach the coveted INR 100 Cr revenue mark in record time. Yet, traditional Indian brands have shown a strange reluctance to adopt pure-play D2C models, unlike the US, where businesses stay in charge of the entire cycle (right from procurement to manufacturing to shipping and last-mile delivery) without spending too much capital or resource in non-core activities.

The narrative seems to be changing in India as well. Much as one likes to stay in control, most brands are now seeking third-party services instead of developing in-house capabilities to cut down on costs and cut through the complicated mesh of end-to-end operations. In essence, smart businesses now love to stay lean and agile to focus on their core competencies and succeed fast. And the quick implementation of this business rationale is clearly helping the new-age, tech-first D2C brands rise and shine.

Mirror, Mirror On The Wall, What’s The Toughest Of Them All…

A modern-day business has its magic mirror too, in the form of analytics, metrics and playbooks, and knows a harsh reality or two that can easily topple a newbie. Of all business operations, the one that literally eludes the control of the D2C ecosystem is logistics management. Be it warehousing or inventory management, last-mile delivery or reverse logistics, operational complexities, price opaqueness and legacy issues such as fleet under-utilisation have driven most brands to third-party logistics (3PL) services as a safer bet. But in a market thickly populated with 3PL aggregators, independent courier companies, ecommerce marketplaces, hyperlocal delivery services and other shipping partners, choosing the right company often becomes a tough task.

“As a brand grows, logistics operations can quickly become tricky, leading to cost escalations and erosion of profits. At this juncture, businesses should explore opportunities to partner with a logistics solution provider that have expertise in end-to-end supply chain management. This will bring operational efficiencies and customer satisfaction in the long run,” says Ankit Kaushik, cofounder and COO of Pickrr, a Gurugram-based third-party logistics aggregator.

The emphasis on logistics management will also trigger huge growth opportunities for D2C brands. After all, the growth of an ecommerce/digital commerce firm primarily depends on the size of its customer base and the company’s ability to deliver to as many pin codes as possible. Partnering with the right logistics companies means brands can improve their geographical reach, throwing open more avenues for revenue generation. Better still, they will be able to guarantee fast and (at times) free shipping as reliable players have proven expertise in areas like storing, packing, shipping and last-mile delivery.

Logistics gone awry can also impact a brand’s image. Due to resource crunch, many small and medium-sized D2C brands rely on word-of-mouth promotion to grow sales and acquire new customers. Hence, bad publicity caused by a logistics logjam can permanently damage a brand’s reputation and business opportunities. Moreover, as fast-moving consumer goods (FMCG)/perishable products form a major chunk of the D2C space, a delay/failure in the supply chain can lead to product depreciation and widen losses.

Decoding Logistics Costs

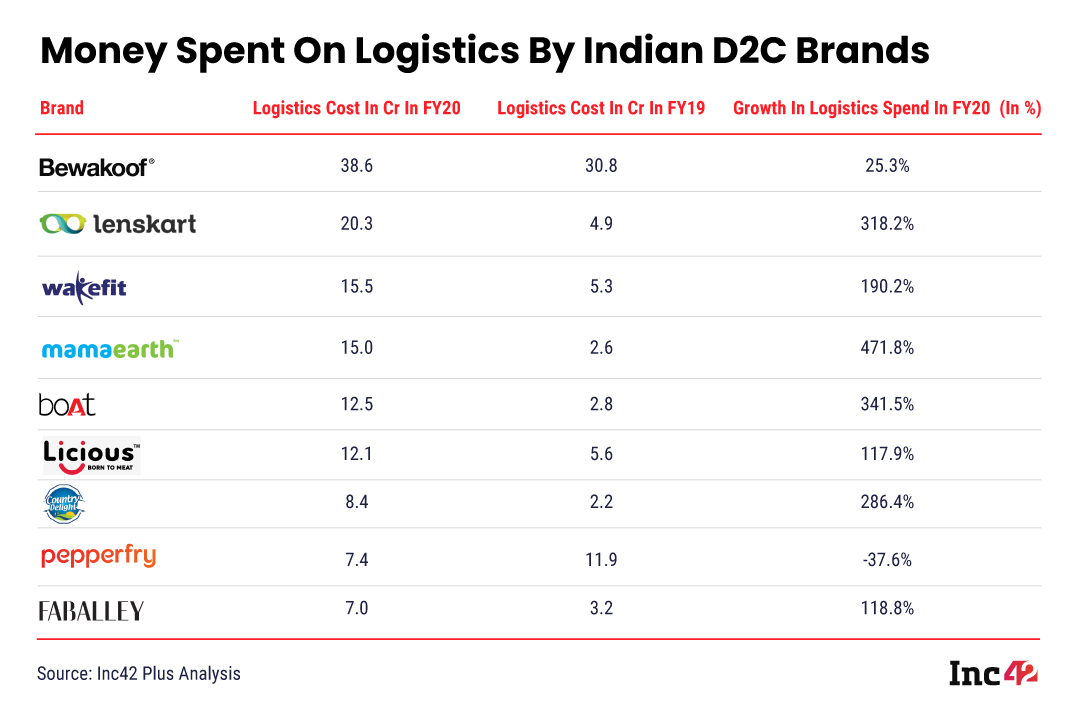

Before we deep-dive into efficient management of logistics operations, a quick look at the latest trend will not be out of context. For example, the data featured below shows the logistics spend of major D2C players in FY19 and FY20 and how the logistics expenditure grew over the financial year. (Mumbai-based furniture brand Pepperfry was the lone exception, and the company saw a 37.6% reduction in logistics spending in spite of the Covid-19 crisis.)

Incidentally, logistics costs could have been on the rise for several reasons. To begin with, it depends on the rise in order volume, especially higher ecommerce sales, and the scale of operations. On the other hand, higher wages (due to manpower shortage), higher warehousing and transportation costs and inefficient management can accelerate spending and hinder business growth. By streamlining these costs and improving the efficiency of the supply chain, D2C brands can calibrate their operations and improve their revenue margins.

Udaipur-based fashion ecommerce brand Beyoung is a case in point that explains how logistics costs, when not optimised, can rapidly become a burden. When the company started in 2015, it handled a low order volume of 1,000 T-shirts a month and used several courier services for order delivery. However, stock administration quickly became a problem for the startup. Its major concern was a high number of RTOs (returns to origin) and NDRs (non-delivery reports) that led to stockpiling, inventory mismanagement and difficulty in getting back undelivered packages.

The brand required a more streamlined process to track orders, keep delivery failures to a minimum and ensure lower return-freight prices for undelivered shipments. Using multiple courier services helped it reach more pin codes, but the startup was compelled to co-ordinate with each service separately and pay different prices. The brand required more people to handle these operations and also paid more for deliveries as there was no price standardisation.

To optimise logistics costs, Beyoung partnered with Pickrr in 2016, and the 3PL company used its network of courier services to ensure timely product delivery. What’s more, the brand was able to minimise RTOs and bring down non-deliveries by leveraging Pickrr’s order tracking and inventory management systems. Consequently, the startup saw a 20% reduction in logistics expenses as the prices became more standardised. It further increased its service areas to 27,000 pin codes with the help of Pickrr’s network, and scaled its order volume from 1,000 to 60K orders per month.

“D2C brands are growing rapidly, but the market is driven by fierce competition. Brands must optimise their expenditure on transportation, logistics and last-mile delivery to ensure that profits are preserved. Also, bringing efficiency, agility and transparency will contribute to customer satisfaction,” says Kaushik of Pickrr.

Why Bulk Orders Increase Logistics Costs

One of the biggest reasons behind cost escalation is inventory accumulation that may be difficult to move during a sales slowdown or a complete pause. Most businesses prefer ordering in bulk but often fail to analyse time-specific requirements. Unless some ‘hot’ items are flying off the shelves (face masks and sanitisers are good examples in this Covid era), excess inventories, especially rarely purchased items, are bound to trigger high storage costs. So, it is imperative that new-age D2C brands, or any business for that matter, should monitor inventories in real time and ensure agile procurement to reduce supply chain costs. Analysing sales data and identifying most-preferred sales channels also provide insights into expected business growth and help improve bulk order efficiency. Finally, better inventory management also results in market risk mitigation and an optimal product mix as the latter attracts more customers.

Mumbai-based D2C brand WatchOut Wearables has adopted a unique approach to reduce waste on bulk orders. The startup procures a wide range of components such as integrated circuits, micro speakers, transceivers and sensors to manufacture smartwatches and has a couple of strategies in place to minimise its inventory. First, procurement is done for high-value pre-ordered products and this largely eliminates waste. Second, as the startup deals in a specific product category, all its inventory items are used up during the development process and there is very little waste. For instance, component A can be used for product A or product B, C, or D, as all of them are smartwatches and have common components. So, the cost of excess inventory or storage space (given the nature of the products) is not a big challenge here.

However, there is one concern. The startup currently handles 300 orders a month, and a limited inventory works well at this stage. But this may not be a viable option when order volume grows or the company gets into after-sales support in a big way, which may witness unplanned demand for additional components.

Abhisek B., cofounder and CEO of WatchOut, has told Inc42 that the startup considers warehouse management and stock inventory checking an integral part of its operation. When its SKUs increase, the startup plans to digitise its entire inventory operations and sales data to organise all bulk orders dynamically.

Why Evaluating Courier Partners Matters

For small businesses and early D2C brands, where streamlining logistics is not a primary concern, partnering directly with courier services may also be a good solution as it offers direct contact with the shipping company and last-mile deliveries can be better managed.

The key to choosing the right company depends on the needs and the operational model of a D2C brand. In a sense, every company is unique, and so is the need for a courier partner that will be one of the most critical touch points between a business and its customers. With plenty of players to choose from, all with their specific advantages and price ranges, a brand’s decision should be based on analysing and evaluating the business structures of courier companies. Key factors to consider here include the geographical presence, the nature of the products delivered, timeliness of the service, price points and more.

Take, for example, Delhi-NCR-based Delhivery, a 2019 unicorn well known for its expansive reach and air and ground transportation services. However, its shipments come at a higher price point. In contrast, Pune-based Xpressbees only provides ground transportation, takes more time than Delhivery but comes at a cheaper price point. If a D2C brand sells perishable or high-value products that require secure packaging and fast delivery, it makes sense to partner with the likes of Delhivery. On the other hand, those selling low-value non-perishable items may choose lighter packaging and slower delivery to save on dead weight and margins. For such companies, Xpressbees could be the right option due to its price advantage.

Optimising Packaging Metrics Help

A shipment is a physical object that takes up physical space. Efficient packaging (takes less space) that is tamper-proof and has a winning appearance is the dream of any brand trying to ensure better space utilisation and maximum cost reduction without compromising key packaging metrics. On the other hand, inefficient or over-packaging can significantly increase transit and warehousing costs. Even the material used to secure the product can add up, leaving less space for the actual item.

If a D2C brand opts for wooden pallets to secure a product while it is in transit, the pallets will add to the consignment weight, require more storage and vehicle space and eventually incur more cost. But using lightweight carbon frames will immediately reduce the overall weight of the package and ensure that less space is required when it is transported.

On the face of it, it may seem like a minor adjustment with little cost impact. But when a D2C brand sees a higher order volume, more frequent deliveries and a wide assortment of merchandise in transit, packaging optimisation can help mitigate a serious cost burden.

“One area where brands can immediately take action is packaging. Carriers cite over-packing as a key reason for cost escalation. On the other hand, poor packaging not just hampers customers’ perception of the brand but also leads to higher RTOs, ultimately impacting the bottom lines negatively,” says Kaushik of Pickrr.

Investing In Automation Is The Need Of The Hour

The necessity of automation in logistics cannot be denied. From inventory management to warehouse optimisation to delivery tracking, optimum efficiency can only be attained through tech interventions.

The usage of robotics has become prevalent in warehouses as it reduces the reliance on human resources, while AI-driven tools ensure greater efficiency in packaging and space and time management. Using sensors, IoT and RFID tags, automated equipment have emerged as handy tools in deploying shipping parcels from one location to another within giant warehouses.

Delhi-NCR-based personal care brand Mamaearth has benefited most from these automated solutions. When the D2C brand’s order volume grew exponentially as a result of its aggressive marketing, the startup’s freight and transport expenditure saw a 472% jump to INR 15.05 Cr in FY20.

Mamaearth set up regional warehouses in the latter half of 2020 to reduce delivery delays and cut down on shipping costs. It also invested in logistic tech to deploy AI-driven inventory forecasting, warehouse automation and inventory tracking to streamline and optimise its processes.

Leveraging Third-Party Services To Cut Costs

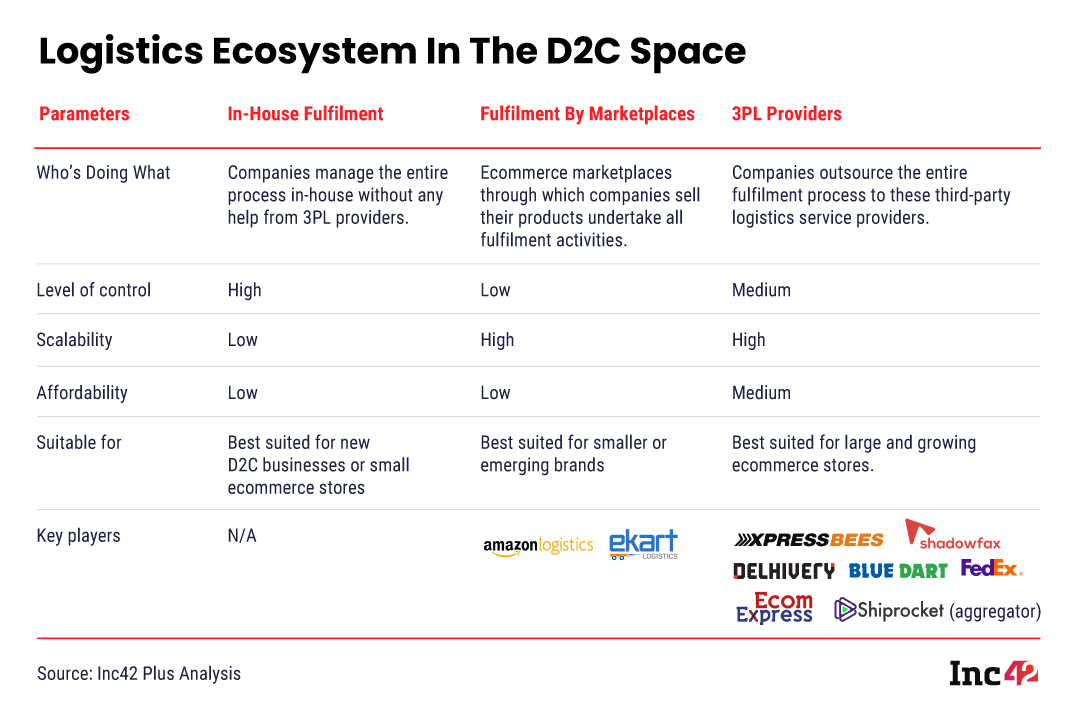

The strategies mentioned above are some of the best practices a D2C business can adopt to run its logistics operations in a hassle-free, cost-effective manner. But given the lack of resources to develop cutting-edge logistics capabilities, many brands prefer the services of third-party providers (3PL aggregators/independent courier partners). Here is a detailed look at how these logistics enablers are helping D2C brands. .

Marketplace Optimisation

Popular ecommerce marketplaces (both vertical and horizontal), including Amazon, Flipkart, Pepperfry, Purplle, Qtrove and more, help D2C players with digital commerce capabilities. This may not be termed as a pure-play D2C model, but little-known brands that are new to online selling or do not have the funds to spend on brand building, customer acquisition and logistics expenditure often find it a suitable compromise.

To begin with, marketplaces provide D2C businesses a secure platform to sell their products to a massive consumer base. They also take complete control of the fulfilment part (warehousing, packaging, delivery), while brands’ role is limited to presenting their products on the platforms and attracting consumers. On the downside, these marketplaces charge a referral fee per transaction, eating into a brand’s profit and hindering its growth in the long run. Even then, many prominent D2C players like boAt, Mamaearth, mCaffeine, Cureveda and more still sell on these marketplaces for better traction in spite of owning their dedicated websites.

How 3PL Companies Are Helping

3PL aggregators in India have come a long way, and given the large-scale adoption of online shopping, their shipments jumped 70% in the October-December quarter in 2020, according to an IANS report. Most of these players offer end-to-end logistics solutions, including inventory management, warehousing, shipping and last-mile delivery. In fact, startups like Shiprocket, Shipway, Pickrr and more, popularly known as D2C enablers, have helped hundreds of brands streamline these operations for scaling up fast.

However, these logistics tech aggregators are still working on a key challenge — they need to develop custom solutions for their clients. As D2C brands come in all shapes and sizes, their requirements vary widely, and a one-size-fits-all mantra does not work in this space. For instance, one brand may require local and global shipping for fragile items, which means it needs a service present in India and overseas that guarantees ‘safe passage’ moving and storage of goods. . Another brand with an FMCG product and small-scale operations may only require pan-India support and fast delivery.

Different brands will also have different fulfilment needs, warehousing requirements and customised tracking solutions. And the ability of these 3PL players to offer a host of versatile solutions for individual organisations makes them a popular choice.

“Partnering with a third-party logistics provider helps a seller utilise workflow automation, significantly drive down logistics costs, enhance customer satisfaction, and most importantly, allows the brand enough time and means to focus on other key areas of the venture that might have been neglected earlier,” says Saahil Goel, cofounder and CEO of Delhi-based Shiprocket.

But just like marketplaces, the 3PL model has certain downsides. In this case, a brand has to set up its online sales platform and build its customer base, a tough task for a new entrant to the ecommerce space. Then again, 3PL players simply tie up with courier services for last-mile delivery — they are not directly involved in it. Hence, there could be more non-delivery issues compared to independent shipping companies with in-house operations.

The Future Of Logistics For D2C Brands

Even today, the logistics industry has its own set of challenges that need to be solved to improve efficiency and reduce costs for businesses. There are plenty of issues regarding reverse logistics, route optimisation, warehousing and real-time tracking of goods, forcing businesses to cough up more money than they should pay. Unless logistics tech evolves fast and emerges as a mainstream business practice, D2C brands, as well as other small and medium businesses, will continue to suffer.

Better road links, smart transportation technologies and pan-India mobile and internet connectivity are also required to replace outdated and deteriorating infrastructure, badly in need of repair. Think of real-time tracking minus the linkage. Or how the lack of roadways are adding to hidden costs. “Whenever we have to ship a product to a remote area like eastern Assam or the depth of Chhattisgarh, we rely on the Indian Post in spite of high delivery charges as there is no other way to reach those pin codes,” says Abhisek B. of WatchOut Wearables.

However, the nation is adapting, albeit slowly. The fast-growing digital penetration has ushered in a massive customer base to the online space. And first-time online consumers from ‘Bharat’ are helping open multiple business opportunities for D2C brands. In 2020, the National Highway Authority of India announced 23 new expressways covering 7,800 km. Together, these projects will ensure better land transportation, reduce logistics costs and bring in new sets of customers so that D2C brands can thrive and grow.

The post How Indian D2C Brands Are Optimising Logistics To Reduce Costs And Grow In A Competitive Market appeared first on Inc42 Media.

0 Comments